Manufacture

In all likelihood, a production bike is the fastest way to distribute Crownring. Generally, the majority of bike owners never alter their bikes. They buy new ones. When Crownring is accepted as the most efficient chainring, any bicycle featuring the Crownring will take a greater share of the market. As there are more than an estimated 650 bicycle brands, the market is big enough to support a new brand. Having the benefit of the Crownring would make the new brand stand out among the others.

There are several ways to roll out a new brand:

- Buy generically and modify to the new brand properties.

- Secure elements and assemble the new brand.

- Build a plant to manufacture frames, secure remaining components and build from scratch.

- Buyout an existing bicycle company and retool for the new brand.

- Outsource the build.

By producing our own brand of bicycle we limit the demand for Crownrings. Crownring production would be set by our brand sales and distribution.

Lets look at demand. Build a bike, make a Crownring. It sounds simple. But what is it that will drive demand? Crownring offers two advantages over other chainrings, both round and oval. Crownring is just easier. That is going to appeal to a wide range of cyclists encouraging them to ride farther and more often. Also many that find cycling to be too difficult, it will see them climb back onto their bikes.

We are facing a climate crisis. The more that people ride bikes for their travels the more it reduces Co2 in our atmosphere. Crownring is going to appeal to the conservationists. Demand is going to exceed the capacity of any one producer.

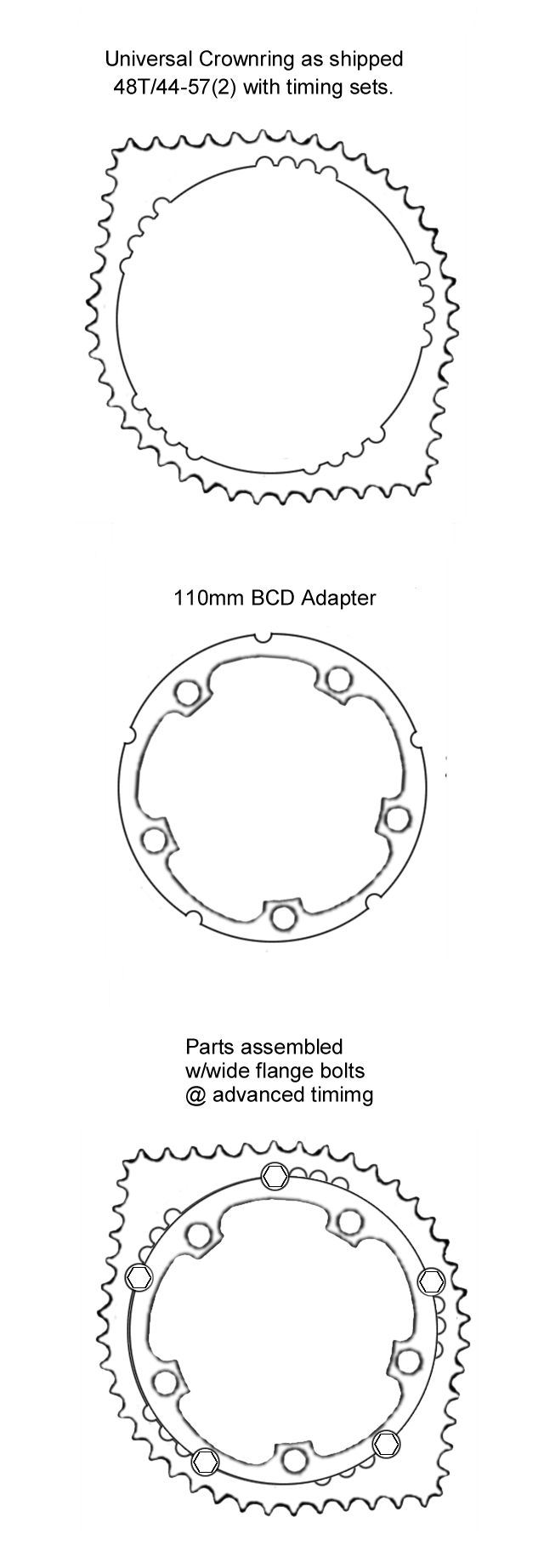

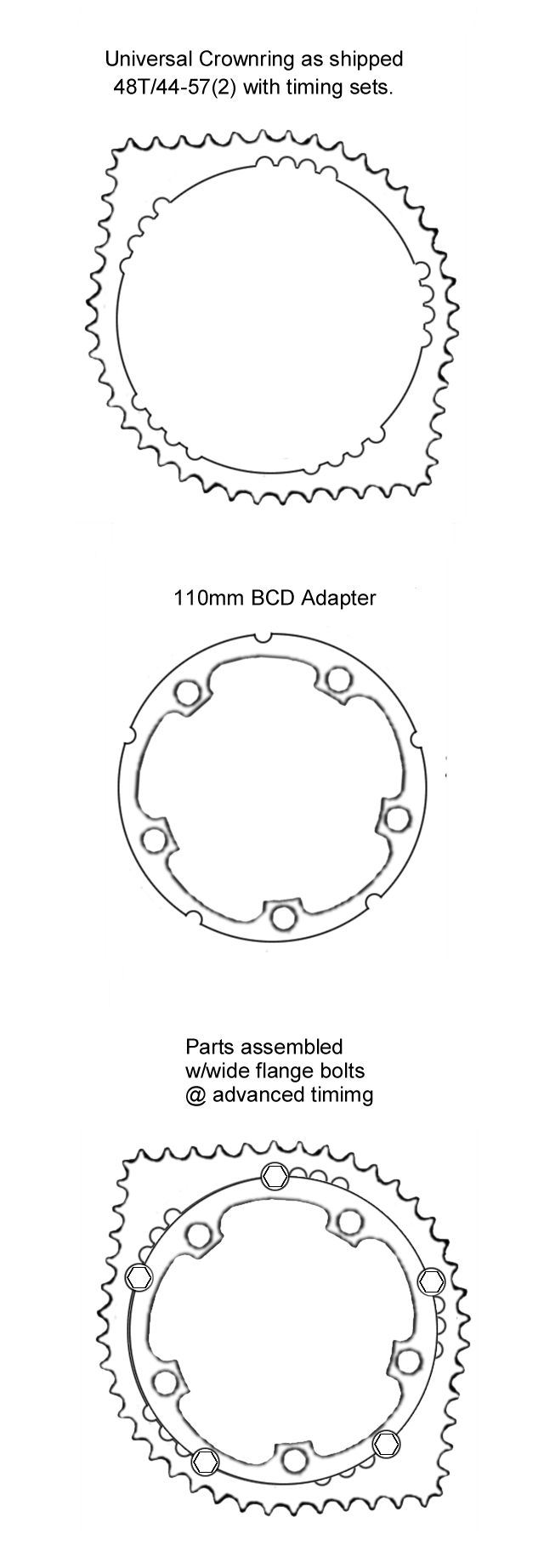

My hope is not to produce Crownrings for every bicycle manufacturer, but to produce a Crownring that will fit any bicycle being manufactured. Adapters will be required but it will be the responsibility of each producer to adapt the universal Crownring to their crank axles. To have an idea of the adapter imagine a chainring without any teeth. The universal Crownring would slips on and be secured with bolts.

Because of the circular mounting system, Crownring timing could be easily adjusted by anyone with minimal understanding. And should they get the timing wrong it takes only a minute to correct.

The universal mount removes the need to produce a score of different mounts, and simplifies the timing factor. Its limited intricacy reduces milling time and increases production rate providing for lower retail cost to consumers.

By not having to produce for every mount on the market, production rates are drastically improved, and availability will never suffer for lack of compatibility.

Further, the universal mount allows simple swapping between Crownrings making it more likely for users to experiment with different Crownring profiles to best suit their styles, thus increasing aftermarket sales.

Lastly, any chainring currently in existence can be rounded to fit the universal mount thus making adaptation an absolutely simple process on any bike anywhere. It is true not everyone is able to trim down a metal chainring with simplicity and precision, but any bike shop can easily tool up to do the job quickly and affordably. Even bikes with Direct-mount chainrings, as most inexpensive bikes are produced, can be adapted to Crownring making it possible to have a Crownring on every bicycle produced past, present, and future.

Another feature to make Crownring more adaptable is to employ the narrow/wide process. This would make a single Crownring width fit both the narrow 3/32" chain and the wider and more common 1/8" chain, again reducing the quantity of production. Narrow/wide is not without its pitfalls. It is poorly suited to a 3/32" chain on multi ring drive, as the narrow link can fall on a wide tooth and refuse to mesh. Narrow/wide is best suited to single chainring drives. And there are Intellectual Property issues that could be infringed without critical design considerations. There are public domain narrow/wide designs and there are protected narrow/wide designs. To forego the narrow/wide profile would mean an increase in production to provide for both 3/32" an 1/8" chains. Any adoption of the narrow/wide profile would be purely experimental. Its market could be too small to be concerned with, but the option is still valid. Narrow/wide has its purpose beyond wider adaptability. A test marketing wouldn't be unreasonable.

At the end of it, universal Crownring will need to be produced with varied T-values, and varied crown sizes, but in addition, and more of a niche market, is the varied "crown stretch" which is explained under the Stretch link in the left panel. However, the universal Crownring mount would reduce production to only three mount variants as opposed to a dozen or more to fit the wide assortment of branded mounts. By requiring each manufacturer to be responsible for their own adapter (a simple matter of their chainring without teeth) Crownring production would only need to cover the 94mm, 110mm, and 130mm BCD. 94mm for small rings, 110 intermediate, and 130mm for large rings.

There are far more variants of Crownring than there are of chainrings, but that is a strength, not a weakness. By providing variants at the three universal mounts anyone can easily and affordably find their best ride. Crownring is the most versatile chainring ever conceived, unmatched anywhere in the market.

More and more chainrings are produced on CNC routers. A sheet of metal, usually aluminum, is put into the CNC router and after 8 to 26 minutes (depending on milling intensity) out comes a chainring ready for paint and polish. The universal mount will eliminate as much as half the milling thus half the time. I think a die cut blank, or cast blank will mill faster yet. Having two systems working simaltaniously would be a time share further reducing production time. That could be important with as many varied profiles that will need to be stocked. And as time is money, faster production means higher profits. Die cut parts are fast and cheap after the expense of the die. Casting would be less initial cost but could be more per blank as they take more manual handling. There is laser and plasma cutting as well. Putting a near complete Crownring into the CNC router is going to result in a quick, high quality product that still meets the standard of the competition.

By all practicality, Crownring is a new bicycle science. It is a new and untapped market. It has the potential to completely displace the chainring market as it is. Crownring will adapt to any bicycle and make it more efficient. While I feel the prudent course would be a new bicycle brand, Crownring could have an extensive aftermarket demand.

Crownring production costs will be the same or less than what the current market sustains now. It replaces old tech with new and better tech, and will do so under its own momentum. It will not be a matter of pushing new concepts onto the buying public. Our only limitation will be our ability to keep up with demand.

Text updated September 13, 2025